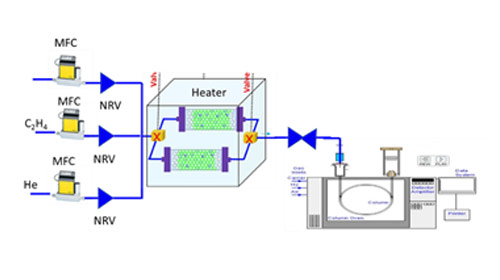

Smart Flow Reactor

Specifications of Smart Flow Reactor:

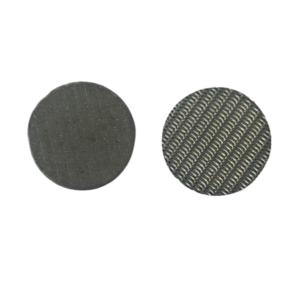

Catalyst Cartridge

M.O.C : SS-316

Reaction type: Gas-gas separation

Total Reactor Volume: 4 ml

Design: ID 3 mm (coiled tube with holder)

Design Pressure: 100 bar

Temperature Range: RT to 500 oC

Nozzles & Fittings: OD 1.6 mm

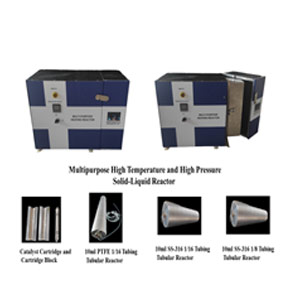

Furnace

Specifications of Furnace

- Inner material:

The inner of the furnace shall be made from ceramic sheath and the same shall be of 25mm dia. X 250mm length split in two halves (single zone).

- Furnace Outer Size:

200 mm square. X 300 mm Ht.

- Heating elements:

The furnace shall have embedded heating element which shall be high density cartridge heaters of 6mm dia. X 200 mm length which shall be placed on the slots created on a SS 304 machined pipe split into two halves. The same shall be capable of operating at any temperature till 500*C with a control accuracy +/-1*C. The rating of each half shall be 600 watts and shall be 1200W for the whole zone. Total rating shall be 1200W, 230V.

GC-TCD/FID

Specifications of GC-TCD/FID

Nucon Series 5765 digital Dual column Gas Chromatograph with:

DUAL FLAME IONISATION DETECTOR:- Microprocessor controls with keyboard entry of process parameters and timing functions with user friendly software in ROM, method development facility and electricity failure back up. Automatic Temperature programming facility with four RAMPS for Oven. Intial mid and final timing and auxiliary temperature Control channel besides oven. Injector and Detector with Auto Dignostics facility & AUTO COOLING FACILITY completete with necessary standard accessories.

WITH BELOW CONFIGURATION:-

- Dual FID single out put with shielding wire with platinum electrode for stability s and noise less signal

- TCD

- Dual packed column injector ports

- Single channel chromatography interface winchrom with software (window based) to be used with your pc

GAS CHROMATOGRAPH WITH BELOW FEATURE: –

All glass system

FID quartz jet

Proven modular system

Imported Cat ridge heaters for base body heating

Platinum temperature sensors

Microprocessor based digital temperature controller

State of art modular chromatography

Wide range of detectors & Automation capability

Provision for two packed / capillary columns

Provision for mechanizer, cryogenic attachment

Multidimensional chromatography

Full line of valves

Modular system, all individual modules like oven, fid & tcd and

data station and computer, printer

Digital Temperature Monitoring for Injector, Oven, Detector and Auxiliary channel of any Swagelok Type International Standard Stainless Steel

Connectors

Output on Terminals for Recorder, Integrator and Data Station

Provided

5 ramp operation, 9 method files for programmable data storage

Auto Diagnostics facility & auto cooling facility

Auto repeat Runs 0- 999

Programming rate 0- 29.9 oC in 0.1 oC step

Provision for Auxiliary temperature controls for feature up gradation GC with any detector

Provision for feature up gradation of any modules like cryogenic attachment, head space attachment and others detector and temperature controllers

All data will be stored and retrieved from the computer at any time

NRV

Specifications of NRV:

Spring based NRV:

Locking with viton Wetting part PTFE Cracking pressure 2 bar

Valve (Manual Valve)

Specifications of Valve:

Material: PTFE

Working Pressure: 1.6-6.4mpa

Working Temperature: -29 oC — +180 oC

Operation Temperature: -10 oC ~150 oC