- Home

- About Us

- New Products

- SCS Product

- SCS Chemical Compounds

- SCS Setup and Accessories

- Electro chemical setup

- Power supply

- Electrochemical Batch Setup

- Valve

- Electrochemical Batch H-cell Reactor Setup with Gas Recator Setup

- Electrochemical Batch H-cell Without Gas Recator Setup

- Electrochemical Batch Reactor and Accessories

- Electrochemical Batch Setup

- Electrochemical Batch Reactor Setup (SCS-EBRS-3CH)

- H-Cell/Divided Electro Batch Reactor (SCS-EBR)

- Smartchemsynth Accessories (SCS-A)

- Products

-

Equipment

Batch Process

- Learning Flow Reactor (SCS-L)

- Photo-Electro Flow Reactor (SCS-PE)

- Continuous Syringe Pump (SCS-CSP)

- High Pressure Syringe Pump (SCS-HPSP)

- Multipurpose Continuous High Pressure Flow Reactor (SCS-C)

- High Temperature and High Pressure Solid-Liquid Reactor (SCS-M)

- Gas Separation and Analysis Equipment (SCS-GS)

- Continuous Flow Hydrogenation Reactor (SCS-HG)

- Liquid-Liquid Separator (SCS-LLS)

- List Item #1

- List Item #2

- List Item #3

-

- Careers

- Contact Us

Smartchemsynth Non-Regulating Valve (SCS-NRV)

Liquid-Liquid Separator (SCS-LL)

Either working in batch or flow, extractions dealing with liquid-liquid are hectic. This product module in the flow chemistry is equivalent of a separatory funnel. Continuous Liquid-Liquid separation works on the principle of polarity difference. By using advanced membrane technology rather than gravity, this liquid-liquid flow separator can separate two-phase mixtures i.e. into the aqueous layer and organic layer. This system/device can separate liquids with the same density and emulsions with continuous operation. The separator has excellent performance when operated with two liquids with very low interfacial tension.

Our liquid-liquid flow separator delivers:

- reduced emulsions compared to batch separation funnels,

- fast partitioning, phase separation and

- is easy to use.

Internal Layers of Liquid-Liquid Separator

Liquid-Liquid Learning Separator 30ml (SCS-LLL-30)

SmartChemSynths Liquid- Liquid Learning Separator Nylon 30ml (SCS-LLL-30N)

SmartChemSynths Liquid-Liquid Learning Separator SS-316 30ml (SCS-LLL-30SS)

Liquid-Liquid learning Separator (SCS-LLL-30) Specifications:

- Pressure: Upto 2 bar

- Flow rate: up to 30 ml/min

- Wetted parts: PTFE

- Dead volume: 700 µL

- Maximum operating pressure: 1 bar

- Temperature Range: 25 to 120 oC

- Membrane: 0.25-0.45-micron PTFE

- Inlet/Outlet ports: 1/16, 1/8, 1/4ʺ-28 UNF

Liquid-Liquid Pilot Separator 200ml (SCS-LLP-200)

SmartChemSynths Liquid- Liquid Pilot Separator SS-316 200ml (SCS-LLP-200SS)

SmartChemSynths Liquid- Liquid Pilot Separator Nylon 200ml (SCS-LLP-200N)

SCS Liquid-Liquid Pilot Separator (SCS-LLP-30) Specifications:

- Pressure: Upto 2 bar

- Flow rate: up to 200 ml/min

- Wetted parts: PTFE

- Dead volume: 20 mL

- Maximum operating pressure: 1 bar

- Temperature Range: 25 to 120 oC

- Membrane: 0.25-0.45-micron PTFE

- Inlet/Outlet ports: 1/8, 1/4ʺ-28 UNF

FUNCTION OF LIQUID-LIQUID SEPARATOR:

When a mixture of two liquids enters the separator composed of aqueous liquid and organic liquid, one phase will have an affinity for the membrane and fill the pores this is referred to as the “wetting” phase), and the other phase will be repelled and will not fill the pores this is referred to as the “non-wetting” phase. Once the membrane pores are filled with the wetting phase, a pressure differential is applied between the two sides of the membrane. The separator is designed to maintain a constant pressure differential across the designated flow rates even when conditions are fluctuating. When a hydrophobic membrane is in place, the organic phase passes through the membrane while the aqueous, which is the non-wetting phase, is retained.

Concept:

The concept of liquid-liquid separator is that it exploits differences in wettability and surface forces to accomplish the separation as a result, the device can separate liquids with the same density and emulsions with continuous operation.

ADVANTAGES

- The separation can be done faster with this liquid separator compared to batch process, and, thus this increases output of product.

- Continuous separation can be achieved which speeds up the overall separation.

- Emulsions and rag layers normally take long periods of time to separate leading to inefficiencies.

- Liquid-liquid separator allows for easy separation of emulsions by removing the matrix fluid and forcing the emulsion to coalesce.

- Since separation is density independent, even the most challenging emulsions can be separated with ease.

Sunflower Equivalent Solar Panel Micro-Flow Reactor

Sunflower Equivalent Solar Panel Micro-Flow Reactor

The breakthrough Sun-flower equivalent solar panel micro-flow reactor by Smartchemsynths Machine (OPC) Pvt. Ltd. has wrapped up together the advantages of continuous flow processing with the added benefits of ultraviolet light to enable photochemical reactions.

By eliminating the problems encountered in traditional batch photochemistry, this reactor allows the full potential of photochemistry to be exploited. It offers safe, efficient, and scalable photochemistry under continuous flow operation.

The ultimate light source has been used which is the Sun. The lights fall on the solar panel which placed at a fixed angle to absorb maximum intensity of light. The solar reactor panel is placed in an acrylic box. This solar reactor panel is in series with pump control panel.

Features:

- Chemically inert tube

- Easy scale-up

- Efficient, uniform irradiation

- Safer in operation

Specifications:

M.O.C | Solar reactor: PFA Setup box: Acrylic Pumps: Nylon (Customizable) |

Reactor vol. | 10ml/min – 1l/min, (customization available as per client requirement) |

Flow rate | 1µl/min – 20µl/min, (customization available as per client requirement) |

Temperature | at RT |

Pressure | upto 10bar |

Solar panel Stand | Each hole at a displacement angle of 100 |

Recommended Android App. For measuring light intensity | LUX Light Meter. |

Smartchemsynth Non-Regulating Valve (SCS-NRV)

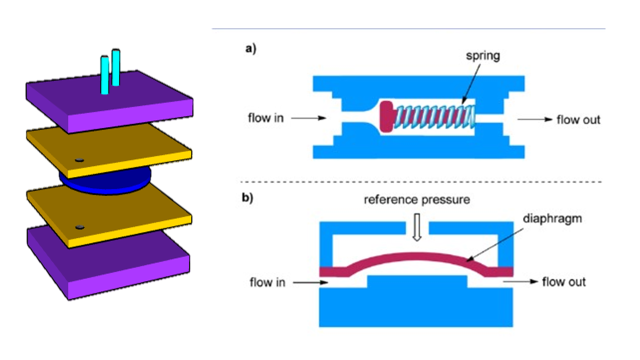

Internal Structure of Non- Regulating Valve

Description

Non-regulating valves are used in cases to limit the flow in one direction. The cracking pressure in these designed valves is to be low.

Specifications of Non- Regulating Valve

- Maximum Pressure: 2-3 Bar

- Outer Body: SS-316

- Wetted Part: PTFE

- Back flow prevention

- Chemical resistance

- Low cracking pressure

- In-line Non-Regulating Valve

- Non-Metallic In-line Non-Regulating Valve

- In-line Cartridge Non-Regulating Valve

- Quick Stop Luer In-line Non-Regulating Valve

- In-line Non-Regulating Valve

- low cracking pressure

- chemical resistance

- back pressure flow regulation

Specifications of In-Line Non-Regulating Valve

| S. NO. | Swept Vol. | Thread Port Config. Flat -Bottom | Max. Pressure | Cracking Pressure | M.O.C |

| 1 | 10µl | 1/4-28 | Upto 25Bar | ±1.5psi (0.1bar) | Nylon, PTFE, SS-316 (customizable) |

| 2 | 20µl | 1/4-28 | Upto 25Bar | ±1.5psi (0.1bar) | Nylon, PTFE, SS-316 (customizable) |

- Non-Metallic In-line Non-Regulating Valve

- back flow prevention

- chemical resistance

- low cracking pressure

Specifications of Non-Metallic In-line Non-Regulating Valve

| SNO | Swept Vol. | Thread Port Config. Flat -Bottom | Max. Pressure | Cracking Pressure | M.O.C |

| 1 | 10µl | 1/4-28 | Upto 25Bar | ±1.5psi (0.1bar) | Nylon, PTFE, (customizable) |

| 2 | 20µl | 10-32 | Upto 25Bar | ±1.5psi (0.1bar) | Nylon, PTFE, (customizable) |

- In-line Cartridge Non-Regulating Valve

- back flow prevention

- chemical resistance

- low cracking pressure

Specifications of In-line Cartridge Non-Regulating Valve

| S. NO. | Swept Vol. | Tube OD | Max. Pressure | Cracking Pressure | M.O.C |

| 1 | 90µl | 1/16ʺ | Upto 25Bar | ±1.5psi (0.1bar) | Nylon, PTFE, (customizable) |

| 2 | 100µl | 1/8ʺ | Upto 25Bar | ±1.5psi (0.1bar) | Nylon, PTFE, (customizable) |

- Quick Stop Luer In-line Non-Regulating Valve

Specifications of Quick Stop In-line Non-Regulating Valve

| S. NO. | Swept Vol. | Thru hole -Luer Adapter | Thread Port Config. Flat -Bottom for Luer Adapter | M.O.C |

| 1 | 100µl | 0.04ʺ | 1/4-28 Luer to thread (Male to Female) | Nylon, PTFE, (customizable) |

| 2 | 120µl | 0.04ʺ | 1/4-28 Luer to thread (Male to Female) | Nylon, PTFE, (customizable) |